FLEX

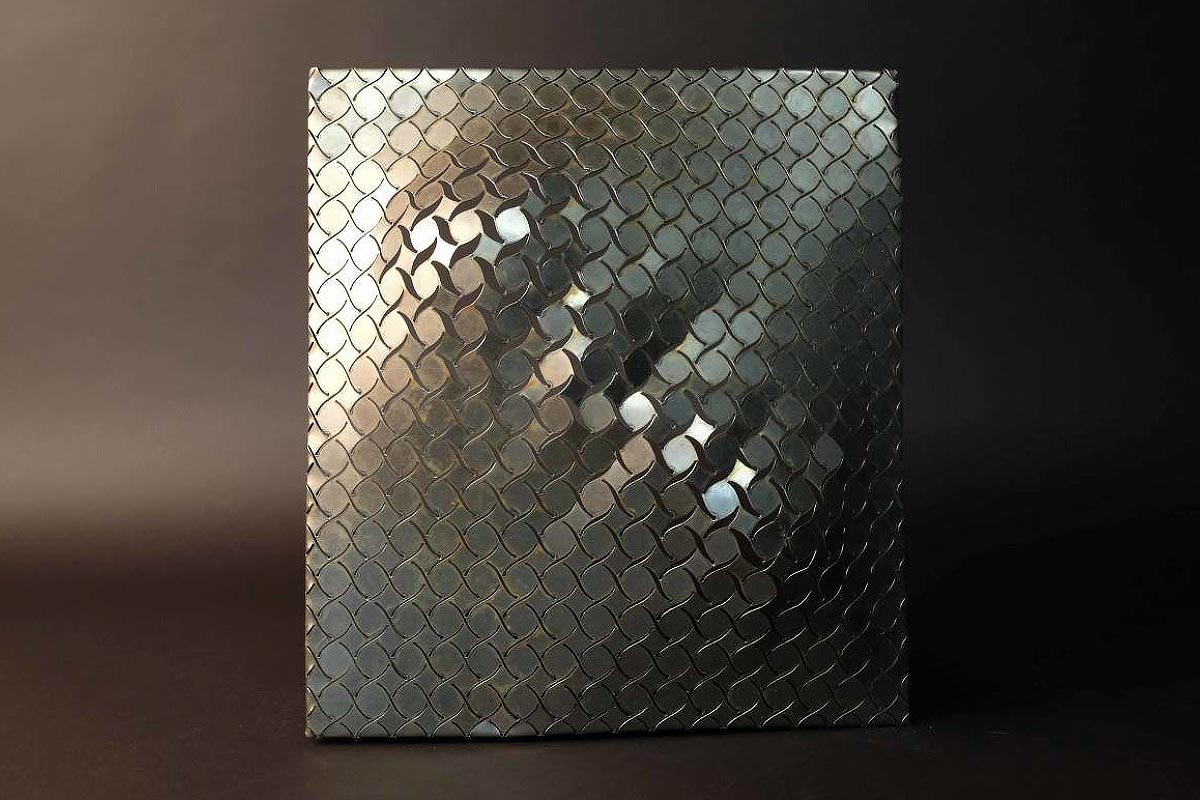

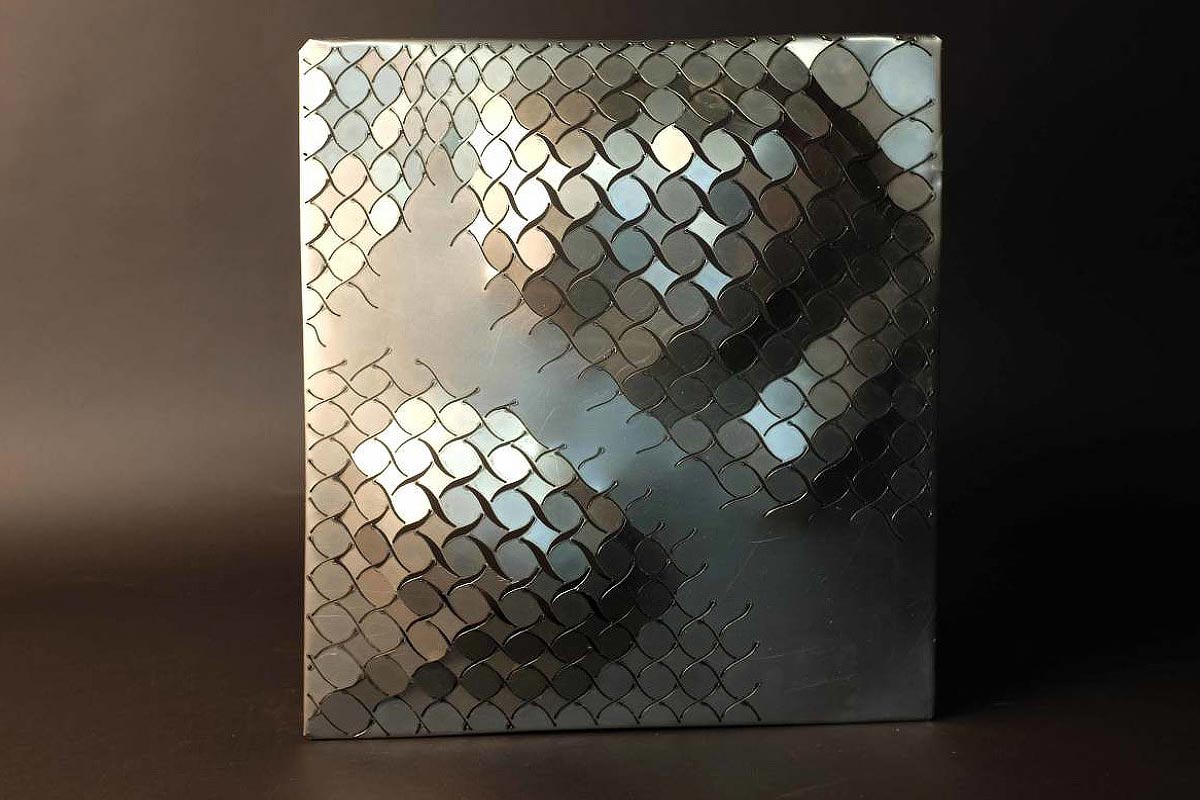

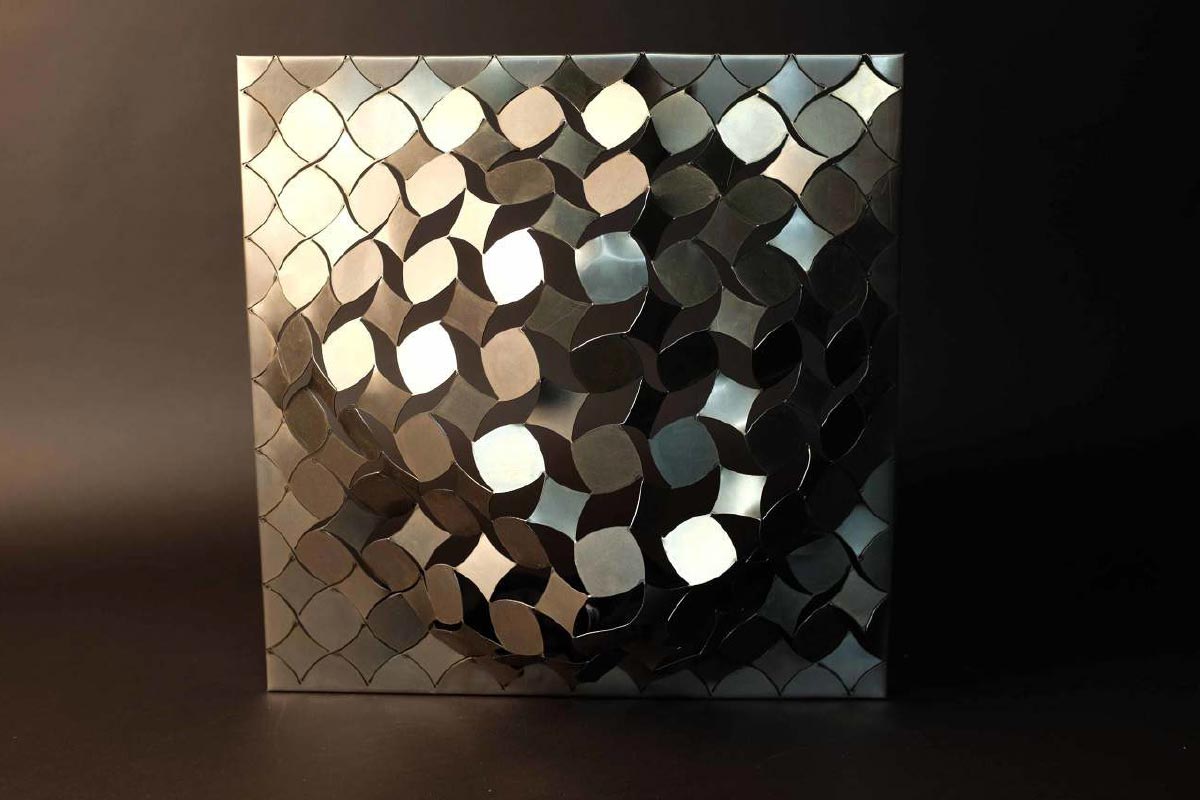

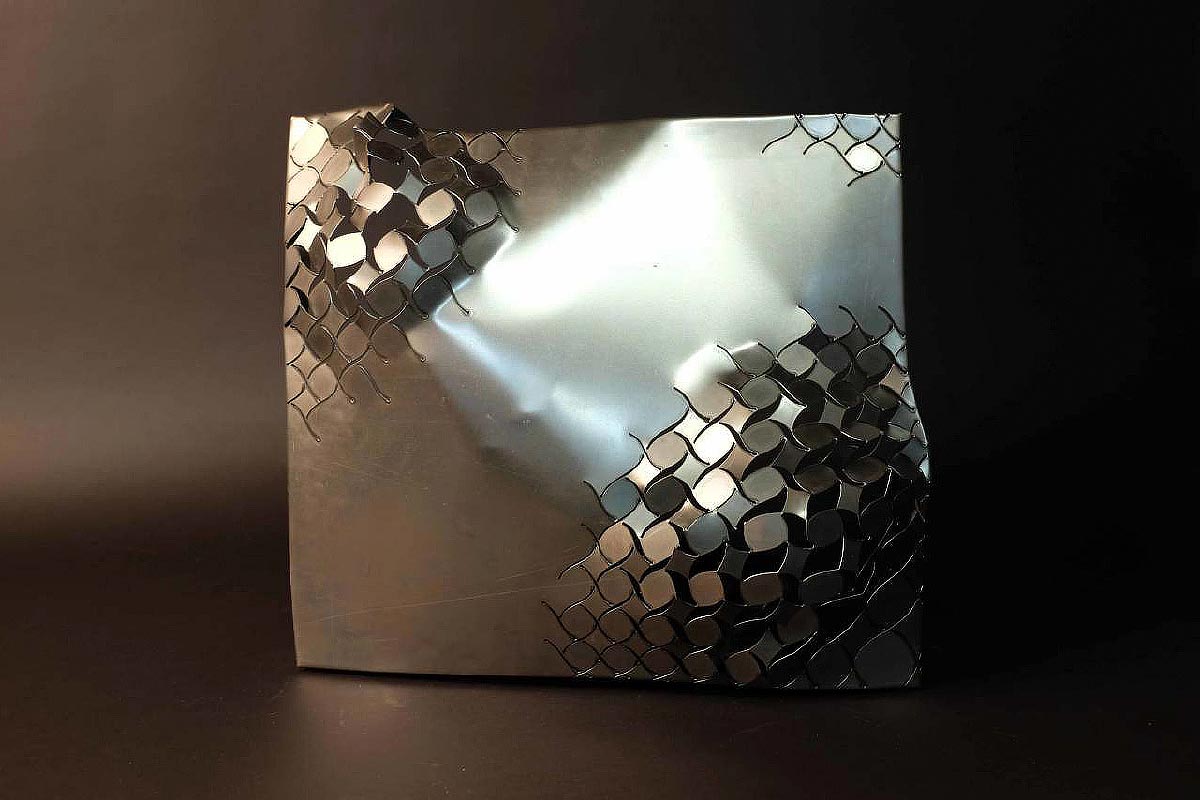

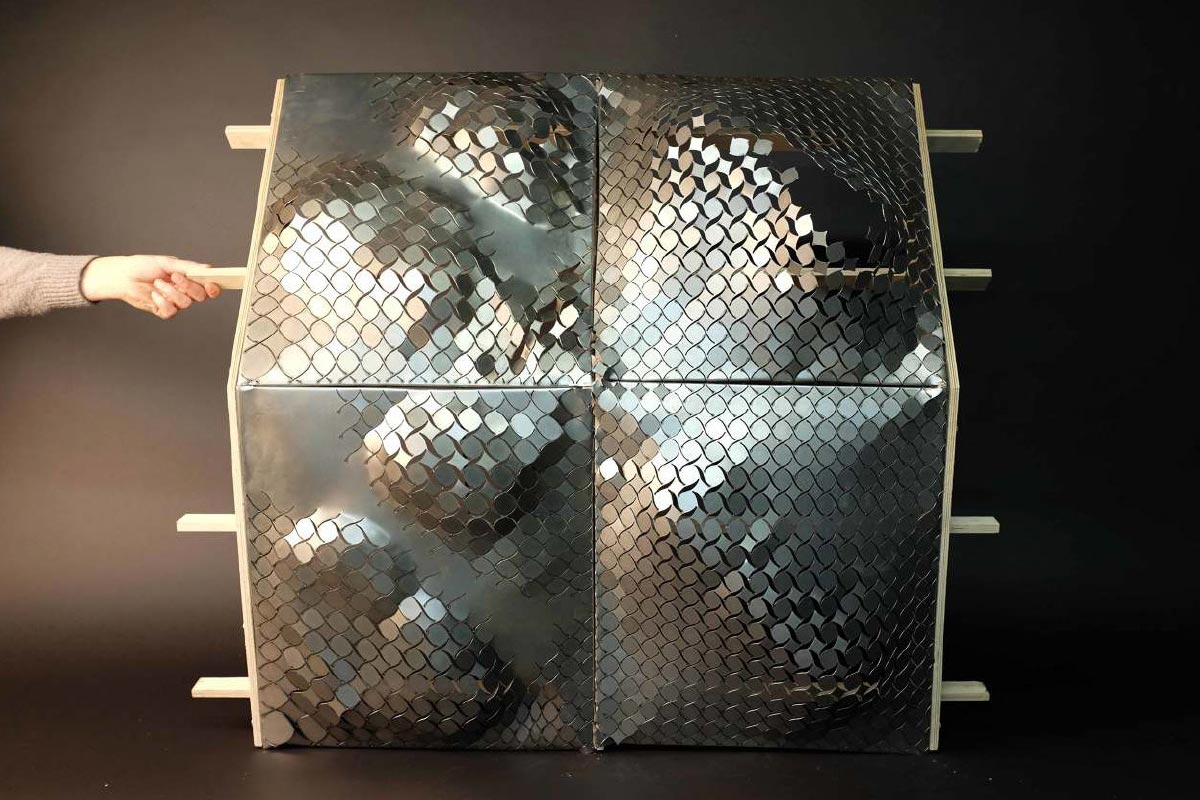

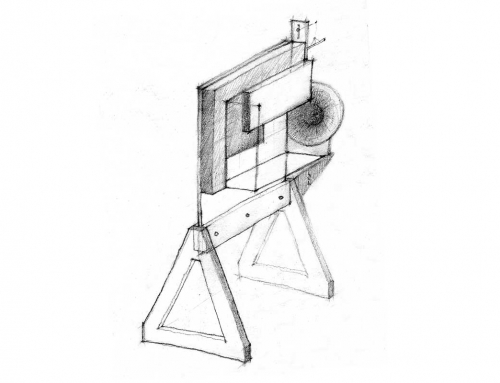

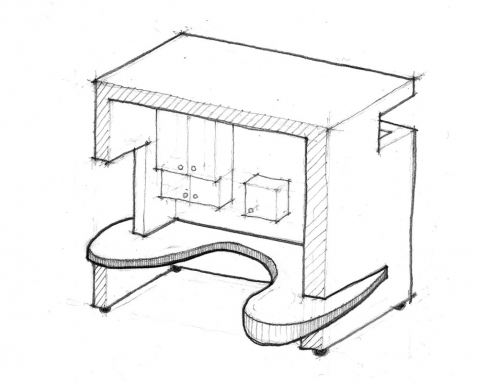

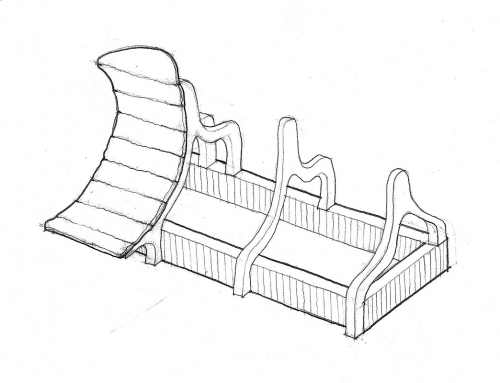

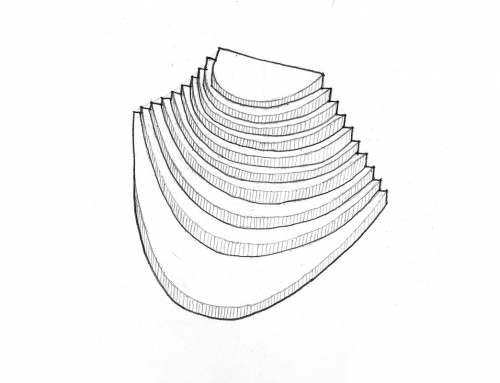

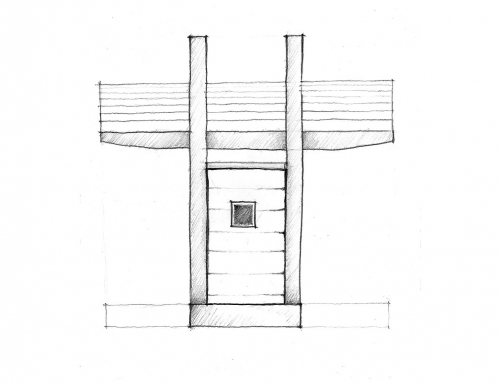

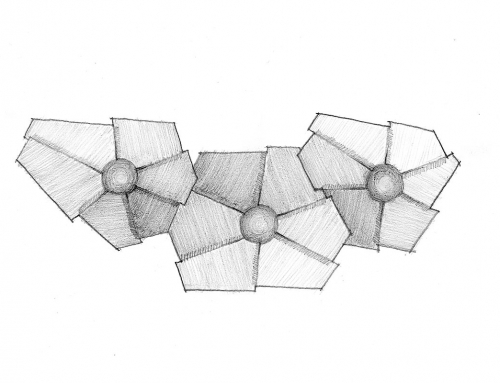

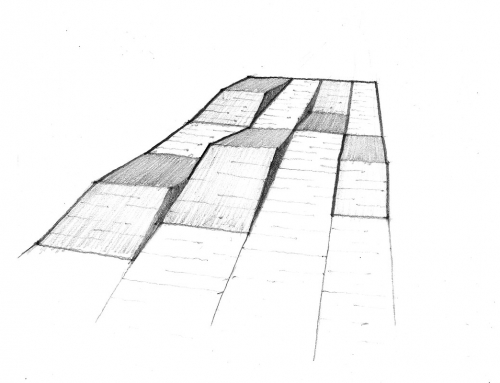

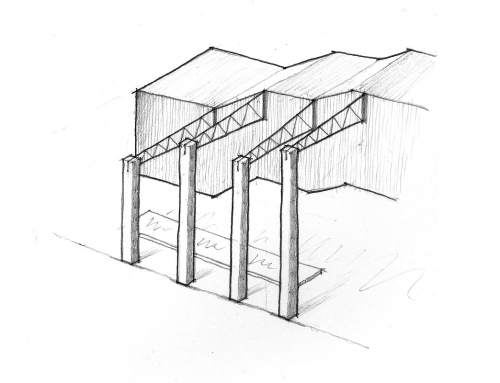

This group project was an exploration in the effects of metal expansion using digital tooling. The ultimate goal was to aggregate expanded metal sheets for Carnegie Mellon’s SoArch Digital Fabrication Lab entry way. Many procedures occurred at once, including the overall entry scheme, metal geometry design via Grasshopper and tool prototyping for an IRB-4400 robot. Metal expansion tests were a major output, done by hand at first and then tested using the robotic arm for potential mass repetition and accurate forms. While tested repeatedly, the robot’s efficiencies were never properly utilized to their maximum potential. What resulted were a series of prototypes which spoke to the volume of experimentation done, but never resulted in a final installation.

Equipment Used:

ABB-IRB-4400 [Expanded Metal Manipulation]

ABB-6640 [Expanded Metal Manipulation]

ABB-IRB 580 [Plasma Cutting]

CNT Motion Systems, 3-Axis Router [Prototyping]

Group Members: Daniel Gehr, Jose Pertierra-Arrojo, Gabriel Vidal-Hallet, Sam Friedman, Sam Day, Andrew Viny